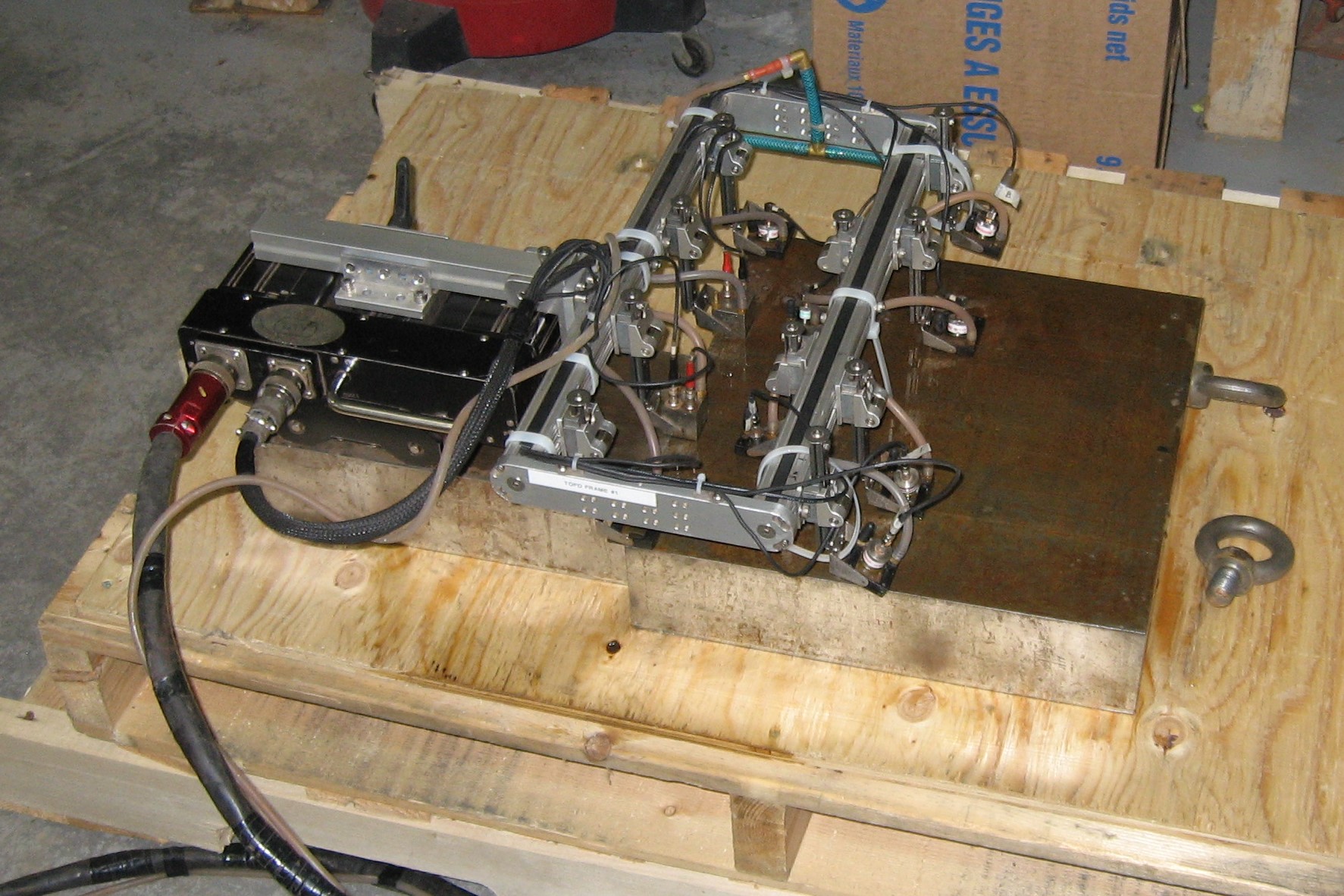

About (TOFD) Services

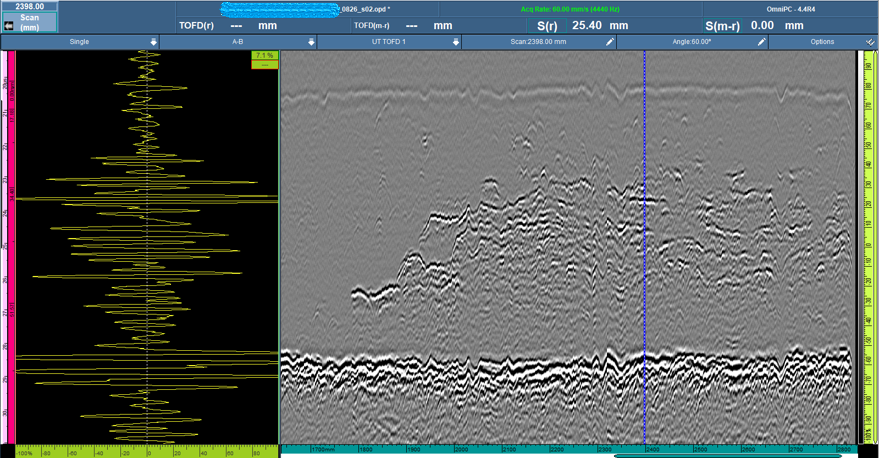

In a TOFD system, a pair of ultrasonic probes sits on opposite sides of a weld. One of the probes, the transmitter, emits a wave generating ultrasonic pulse that is picked up by the probe on the other side, the receiver. In undamaged and clean welds, two main signals are picked up by the receiving probe, originating from a single wave: one that travels along the surface and one that reflects off the back wall. When a defect is present, there is a diffraction of the ultrasonic wave from the tip(s) of the defect. Using the measured time of flight of the pulse(s), the depth and height of a defect can be accurately calculated using simple trigonometry. Length is sized by using the accurately encoded data in computer generated B-scans along the length of the weld.