Phased Array (PA)

Phased Array (PA) is an advanced technology becoming more and more available in the NDT industry to perform full weld inspections, stand alone or in lieu of Radiography. In theory the inspections are similar to conventional Ultrasonic Testing with the added benefit of recording all the data and being able to record multiple angle beams simultaneously. In our standard inspection setups we record the data equivalent to over 60 conventional Ultrasonic (angle) probes.

Phased Array (PA)

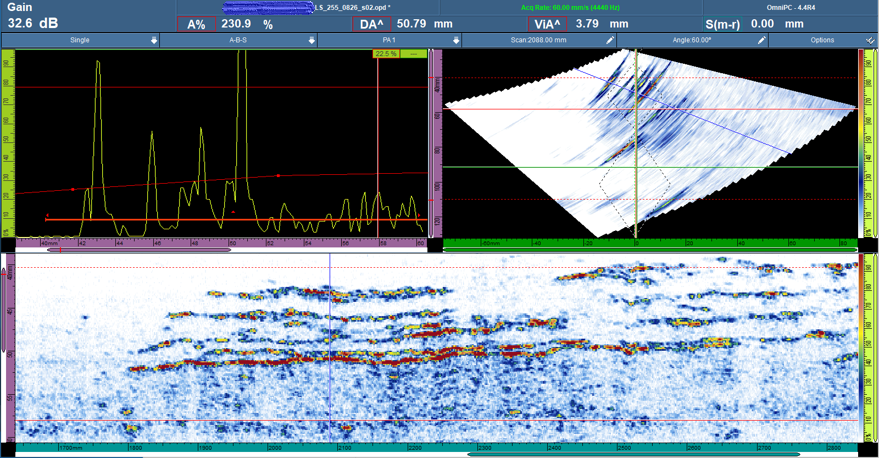

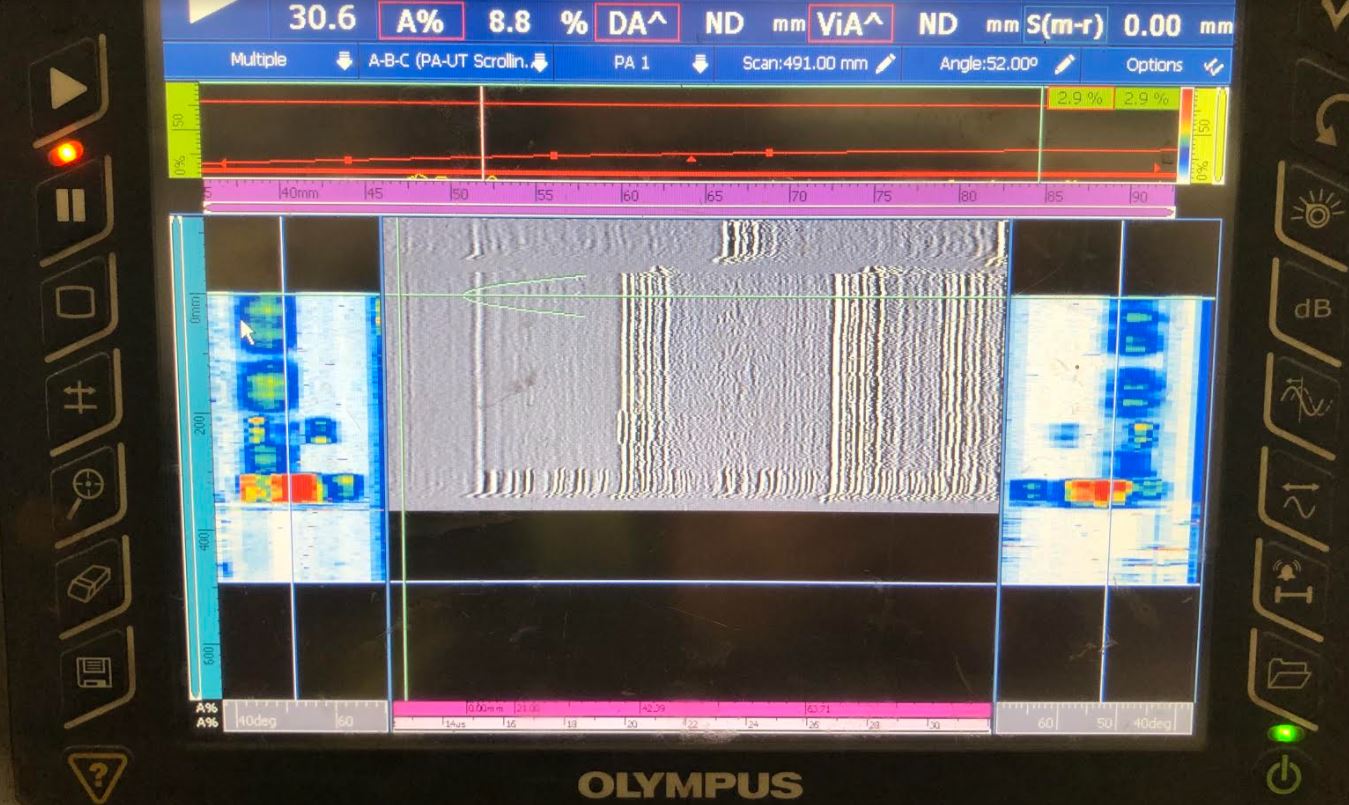

A PA probe consists of many small ultrasonic transducers, each of which can be pulsed independently. By varying the timing, for instance by pulsing the elements one by one in sequence along a row, a pattern of constructive interference is set up that results in a beam at a set angle. In other words, the beam can be steered electronically. The beams can be swept like a search-light (sectorial scanning) or moved from the back to the front of the probe while maintaining a constant angle (linear scanning). The data from multiple beams are put together to make a visual image showing a slice through the object.

Advantages

- Fast, reliable and highly reproducible inspections

- Very efficient and accurate on lower wall thicknesses (1/4 inch and up)

- Is safe for other employees to work around

- Provides a permanent record of inspection

- Computer controlled data acquisition

- Delivers complete volumetric coverage of welds

- Accurate height and length sizing of defects

- Coarse grain materials can be inspected

Limitations

- Longer initial setup and calibration time

- Requires clean inspection surface

- Obstructions on the inspection surface can inhibit access of our scanners

- Less efficient (fast) than TOFD on higher wall thicknesses (3 inches and up)

- Specialized training is required

- Data evaluation requires significant experience and skill