RADIOGRAPHIC TESTING (RT)

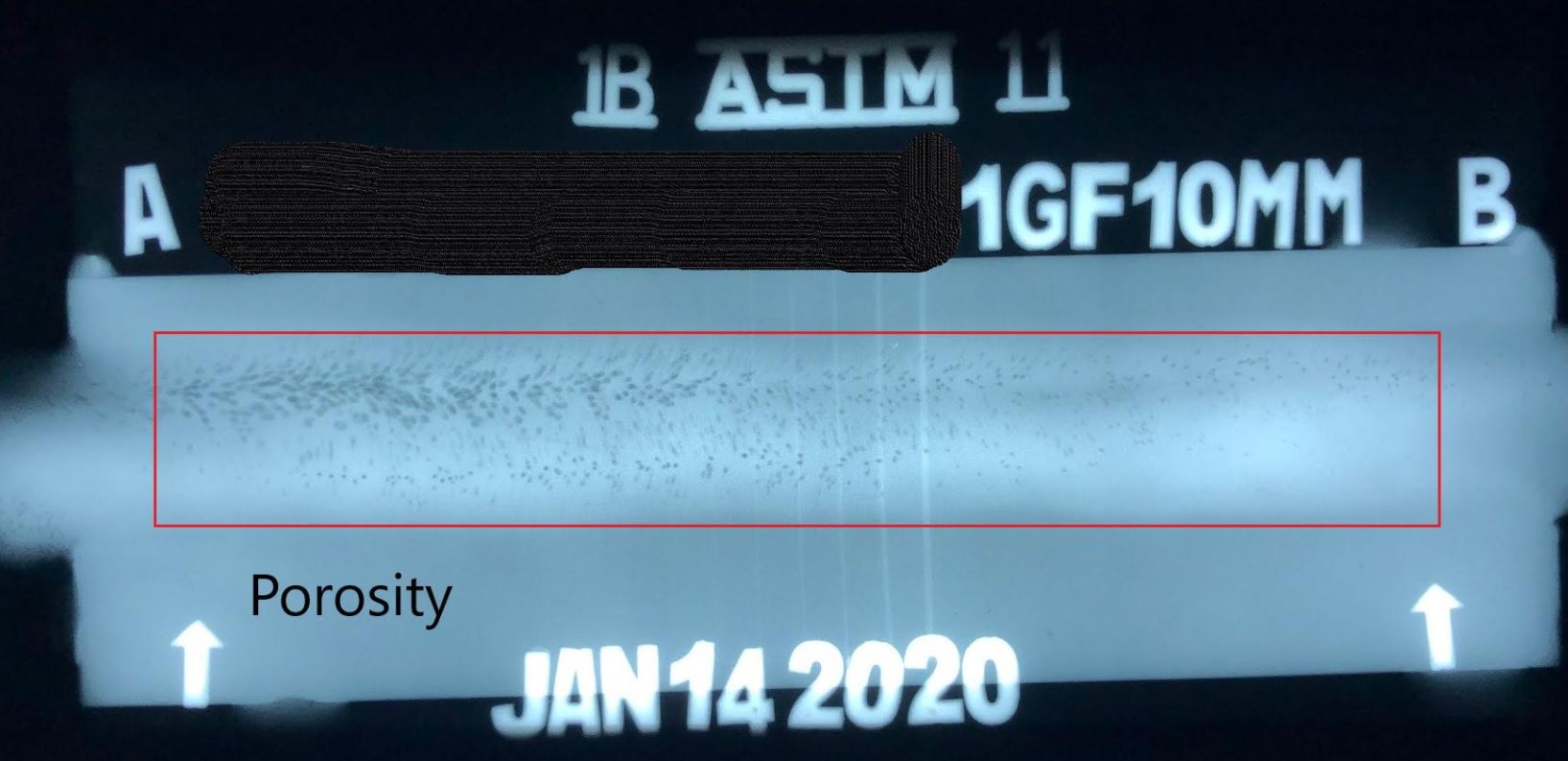

Industrial radiography involves exposing a test object to penetrating radiation (short wavelength) so that the radiation passes through the object, is absorbed in differing amounts according to material density and thickness. The energy emitted on the other side of the object is generally “registered” on recording media which can be industrial x-ray film or one of several types of digital radiation detectors. The image that is registered on the recording media is a shadow image of the material under test. An end effect of having darker areas where more radiation has passed through the part and lighter areas where less radiation has penetrated. If there is a void or defect in the part, more radiation passes through, causing a darker image on the film or detector.

RADIOGRAPHIC TESTING (RT)

For thinner or less dense materials such as aluminum, electrically generated x-radiation (X-rays) are commonly used, and for thicker or denser materials, gamma radiation (radioisotope such as Cobalt 60 or Iridium 192) is generally used.

Radiography is best suited to detecting internal discontinuities which are volumetric.

Advantages

- Permanent record

- No calibration needed for the jobsite

- Excellent method for the detection of internal discontinuities

- Beam direction essentially unaffected by geometry

Limitations

- Radiation hazard

- Depth of discontinuity not indicated

- Orientation of linear discontinuities important

- Relatively expenses

- Limited depth penetration

- Access to both sides required.